What is Slew Ring Bearing?

What is Slew Ring Bearing?

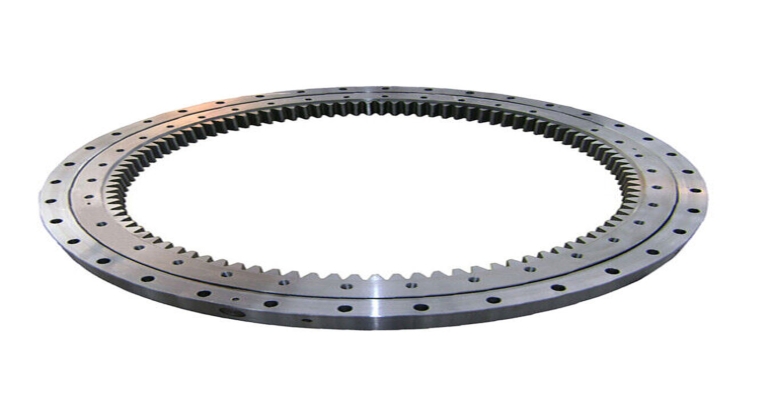

A slew ring bearing, also known as a slewing ring or slewing bearing, is a rotational rolling-element bearing that typically supports a heavy but slow-turning or slow-oscillating load, often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis windmill. Unlike a traditional deep groove ball bearing, slew ring bearings are large in diameter and designed to accommodate higher axial, radial, and moment loads.

Types of Slew Ring Bearings

Slew ring bearings are generally classified into three main types based on their design and the demands of the application:

Single-row ball type (four-point contact): This common type features a single row of steel balls with a four-point contact that can support axial, radial, and moment loads simultaneously. It is suitable for applications requiring high precision and minimal clearance.

Double-row ball type: This type has two rows of rolling elements which allow for greater load capacity and better stability. It is used in applications involving heavier loads.

Crossed roller type: In these bearings, the rollers are arranged in a crossed pattern, which increases the bearing's ability to withstand high axial and radial loads as well as tilting moments. They are typically used in applications requiring high rigidity and minimal deflection.

Features of Slew Ring Bearings

High Load Capacity: Can support high axial, radial, and moment loads.

Compact Design: Integrates an inner and outer ring with a compact design that simplifies the structure of the machinery.

Rotation Flexibility: Facilitates smooth and controlled rotational movement.

Versatility: Available in various sizes and types to fit different applications.

Sealed Units: Often equipped with seals to prevent the ingress of dirt and ensure maintenance-free operation for a longer duration.

Applications of Slew Ring Bearings

Slew ring bearings are used in a variety of applications across different industries:

Cranes and Lifts: Mobile cranes, tower cranes, and boom lifts.

Wind Turbines: Enables the turbine nacelle to rotate smoothly to face the wind.

Medical Equipment: Used in CT scanners and medical chairs for precise movement.

Industrial Machinery: Material handling equipment, bottling machines, and conveyors.

Construction Equipment: Excavators and turntables.

Military Applications: Radar units, missile launchers, and turrets.

Price of Slew Ring Bearings

The price of slew ring bearings can vary widely depending on the size, type, material, and specific application requirements. Prices can range from a few hundred dollars for small, standard bearings to tens of thousands of dollars for large, custom-engineered units.

How to Select Slew Ring Bearings?

Selecting the right slew ring bearing involves several considerations:

Load Characteristics: Consider the type of loads (axial, radial, moment) and the magnitude of each.

Precision Requirements: Determine the required precision and rotational speed.

Environment: Assess the operating environment for factors like temperature, presence of contaminants, or potential for corrosion.

Size and Space Constraints: Evaluate the available space for the bearing in the machinery.

Life Expectancy: Consider the desired lifespan and maintenance capabilities.

Sealing and Lubrication: Ensure appropriate sealing and lubrication for the operating conditions.

By considering these factors, you can select a slew ring bearing that meets the operational demands and longevity requirements of the application.