A Double-row Ball Slewing Ring Bearing is a type of rotary bearing designed to accommodate large and complex load combinations that include axial, radial, and tilting moment loads. As the name suggests, this bearing features two parallel rows of ball elements between the inner and outer rings, providing increased load-carrying capacity and stiffness compared to single-row slewing bearings.

Same diameter double row ball slewing bearings are usually used in wind turbines and concrete pump trucks. In wind turbine applications, double row ball slewing bearings are often installed at the bottom of the propeller for pitch control, requiring zero clearance, large starting friction torque, and high operating accuracy.

External diameter: 200 mm to 10000 mm

Ring material: 42CrMo / 50Mn/ C45

Ball/roller material: GCr15

Quenching hardness of raceway: HRC55-62

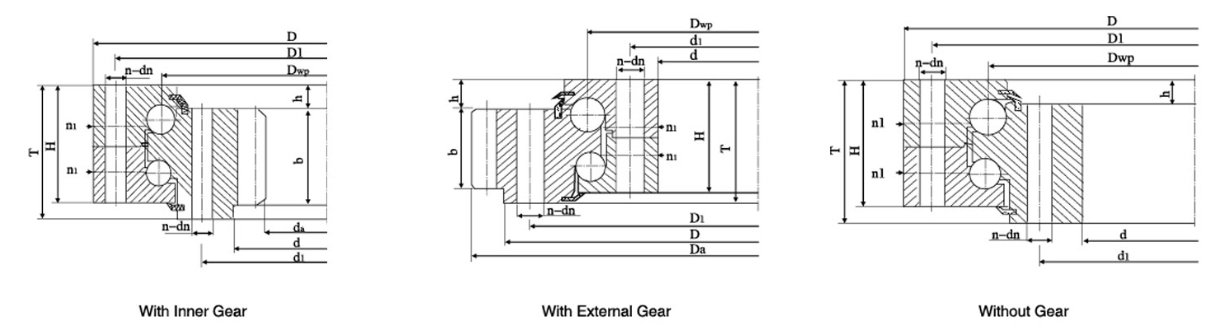

Tooth type: no gear, internal gear, external gear

Lead Time: 10-30 days

What is Double-row Ball Slewing Ring Bearing?

What is Double-row Ball Slewing Ring Bearing?A Double-row Ball Slewing Ring Bearing is a type of rotary bearing designed to handle complex load combinations that include axial, radial, and tilting moment loads. It features two parallel rows of ball elements between the inner and outer rings, providing increased load-carrying capacity and stiffness compared to single-row slewing bearings.

While further categorization based on gear configurations or specific application requirements might be found, the primary type of Double-row Ball Slewing Bearing is:

Double-row Ball Slewing Ring Bearing with Gearing: This type can have internal or external gearing to match the specific requirements of the application. The integrated gearing enables seamless integration with drive systems and additional torque transmission capabilities.

Features of Double-row Ball Slewing Bearing

Higher Load Capacity: The double-row design allows for better load distribution and larger load capacity, making it suitable for heavy-duty applications.

Increased Stiffness: With two rows of ball elements, Double-row Ball Slewing Bearings offer higher stiffness and stronger resistance to deflection compared to single-row slewing bearings.

Versatile Load Handling: Capable of accommodating axial loads in both directions, radial loads, and tilting moment loads.

Compact Design: Despite offering higher load capacity and stiffness, the double-row design allows for compact solutions in space-constrained scenarios.

Customization & Gear Configurations: Can be customized with internal or external gearing, according to the application requirements.

Cranes: Used in tower cranes, crawler cranes, and mobile cranes to provide rotational movement and load support for the boom and jib.

Heavy Lifting Equipment and Machinery: Offer the required load capacity and stability in various industrial applications.

Wind Turbines: Help transfer loads between the nacelle and tower while enabling precise rotation and pitch adjustments.

Excavators: Facilitate the smooth rotation and load handling of the excavator's boom and turret.

The price of a Double-row Ball Slewing Ring Bearing depends on factors such as size, material, load capacity, gear configuration, customizations, and the manufacturer's pricing strategy. It is not possible to provide a specific price without considering these details.

To get an accurate price for a Double-row Ball Slewing Bearing, it is recommended to contact bearing suppliers or manufacturers with the specific requirements and technical specifications of the bearing you need. They can provide a quote based on the exact bearing you require and any additional features or customizations that may be necessary.

Keep in mind that while price is essential, selecting a Double-row Ball Slewing Bearing that meets performance and quality requirements is crucial to ensure the optimal operation and longevity of your application.

Supplier of Double Row Slew Ball Bearing

ZENITH-DRIVE is a professional manufacturer of slewing ball bearings and we can design and manufacture slew ring bearings, precision bearings, slew drives and custom bearings for construction, engineering, mining, marine, chemical, military, wind turbine, medical equipment, and many other industries.

By virtue of expertise team, advanced manufacturing technologies and strict quality management system, ZENITH-DRIVE takes the lead in the R&D of slewing bearings, which are designed with reasonable construction, light weight, good load carrying capacity and high versatility. The bearings’ diameters range from 200 to 10000mm and the accuracy covers PO, P6 and P5 class. Now, we can manufacture CCS, ABS, BV, GL and other certified bearings.

Ring material: 42CrMo / 50Mn/ C45

Ball/roller material: GCr15

Quenching hardness of raceway: HRC55-62

Tooth type: no gear, internal gear, external gear

Lead Time: 10-30 days